Aircraft

Generator used as a welder

Surplus Aircraft Generators have long been used to

make simple arc welders since WWII. The "how to" has been lost as commercial

welders became more economical. This is the "how to" fundamentals for those

wishing to get back to the basics.

How you construct the mechanical parts is up to you, but you will need a 10 hp to 20 hp

motor to drive the generator at 3000 rpms. (200 amp to 400 amp respectively). Light duty

welding may not require a cooling fan but continuous work will require some form of

cooling. This is a good time to tell you that there is plenty of electricity to kill you.

Respect it!

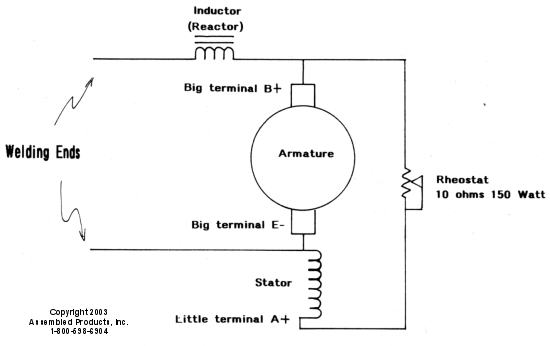

The drawing pretty much tells you how to connect

the wires. Your generator will probably have two additional terminals: a big

"C+" and a little "D". These are use to even the load when it is being

used as a generator on a multi-engine airplane.

The inductor evens the current flow, making it easier to maintain an arc and reduce the

sparking at the brushes. The Inductor is made up of 15 turns of insulated 8-gauge wire

tightly wrapped around a 1-1/2" steel pipe. It is not critical but even 8-gauge wire

will drop voltage and get hot, a larger diameter won’t hurt.

We can’t endorse anyplace to get parts but you might start at www.surpluscenter.com

Our attorney

tells us we must tell you that: this is for information only; we don’t recommend

building a welder over buying one; electricity kills; We’re not responsible for any

damage you may do to anything or yourself; Use eye protection; don’t stand on the top

rung of a ladder; fast food is fattening; smoking causes lung cancer; breathing is

dangerous; everybody is going to die sometime. In other words, be careful and if you do

anything stupid, we are NOT to blame. |